Your trusted partner in precision manufacturing sourcing

Apxt bridges the gap between EU-based companies and reliable CNC machining factories in China. We handle sourcing, quality control, and communication, so you can focus on design, delivery, and growth.

Why Choose Apxt?

We’re not just a broker. We’re designers, engineers, and sourcing professionals with boots on the ground in China and roots in European manufacturing standards.

Trusted factory network — All suppliers are personally audited using a checklist

Technical know-how — We understand engineering drawings, tolerances, materials, and DFM

Bilingual operations — Fluent in Chinese, English, and Finnish for seamless communication

End-to-end support — From RFQ to QA to logistics, we manage the entire process

Flexible volumes — Prototype, small batch, or mid-scale production

Capabilities

We specialize in sourcing high-quality parts and assemblies for industries including:

Industrial products & machinery

Consumer hardware & mobility

Robotics & IoT devices

Product development and prototyping

Core processes:

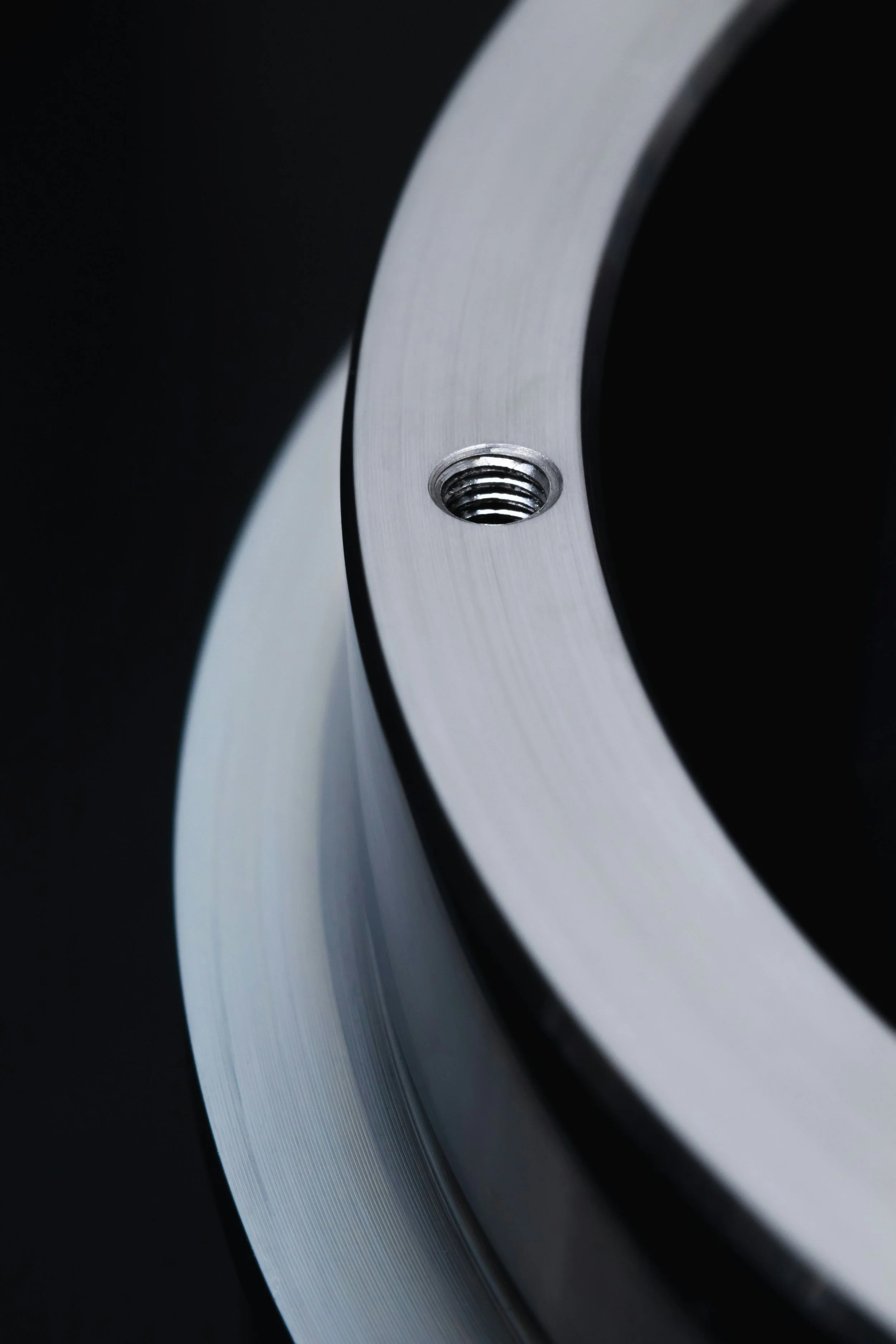

CNC machining (3-axis, 4-axis, 5-axis)

Milling, turning, and complex part production

Surface finishing & coatings

Quality assurance with full documentation

Our Process

1. You send drawings / RFQ

2. We match you with the right factory

3. We audit, quote, and advise on DFM

3. Production begins, we oversee quality control

4. Final inspection & shipping to your doorstep

FAQ

-

We specialize in precision CNC-machined components, including aluminum, steel, brass, and engineering plastics, with optional surface treatments like anodizing, powder coating, or polishing. We support both simple and complex geometries, prototypes and mid-scale batches.

-

We work with clients across:

Industrial equipment & machinery

Consumer products & mobility

Robotics, IoT, and medical devices

Hardware startups and product design studios

If your part requires accuracy, documentation, and timely delivery — we can help.

-

We’re flexible. We handle:

Prototypes (1–10 pcs)

Small batches (10–500 pcs)

Mid-scale production (1,000+ pcs)

Let us know your stage and we’ll tailor the approach.

-

Yes. We offer DFM (Design for Manufacturing) support. That means we’ll review your drawings or 3D models and give feedback on how to simplify machining, reduce costs, and avoid quality issues — before production begins.

-

We personally audit every factory. We also manage:

In-process and final inspections

Full measurement reports (CMM, calipers, etc.)

Visual documentation of finished goods

Final approval before shipment

You get visibility and control, without being on-site.

-

Typical lead times:

Prototypes: 5–10 business days

Small batches: 10–20 days

Mid-production: Varies by complexity

We’ll confirm lead time in your quote and keep you updated throughout.

-

Yes. We can quote FOB, EXW, or DDP depending on your needs. DDP (Delivered Duty Paid) means we take care of everything, factory to your door.

-

Just send us:

A 3D model (.STEP, .IGS)

Technical drawing (with tolerances and materials)

Target quantity and delivery timeframe

We’ll get back to you with a quote and DFM review within 2–3 business days.

-

We specialize in:

CNC machining (3/4/5-axis milling, turning, surface finishing)

Injection molding (prototypes and production tooling)

DFM consultation

Quality control and logistics management

Our sourcing is tailored for functional prototypes, industrial parts, and scalable production.

Get Started

Need reliable CNC manufacturing?

Looking for cost savings without compromising on quality?